Ship loaders

The VIGAN loaders are offering large variety of technical solutions to accommodate the site configuration, the vessel sizes, the importance of operability, the filling efficiency and the dust management.

Our ship loaders are designed up to 2.000 tons/hour for various products. Many layouts are possible, such as fixed/on tires/on rails gantries, with varying height and width, customized boom length, loading spout type, dust control system, control cabin, static or rotating thrower...

Instead of pushing a standard machine, VIGAN proposes to the customer the right compromise between those key design items and a cost-effective solution. The final set-up is tailor-made based upon customer’s needs and requests to produce the most efficient and reliable solution possible. Each machine produced is unique.

Key features

High customization

VIGAN proposes a high degree customization for its ship loader to match product, flowrate, operability and site needs.

Dust management

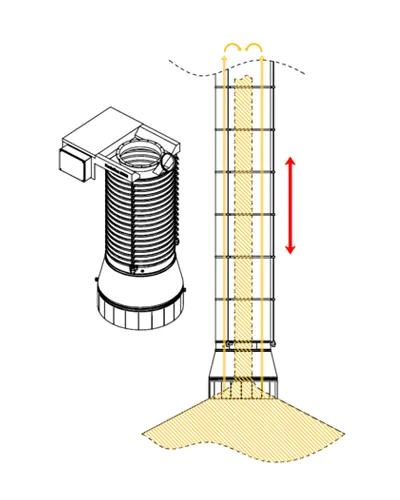

One of the key subjects in loading is dust. VIGAN has a unique approach to guarantee dust free loading operation by providing the best hatch coverage solutions.

Designed for high volumes

At VIGAN, we design loaders for high volumes. It means that we want to prevent the changes of equipment and parts due to wear by design or by the equipment quality.

Loading possibilities

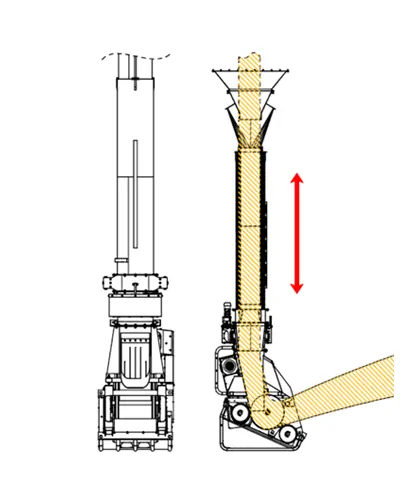

Adaptation to site

Gantry

Various possibilities from fix solution to gantry on rails or tires.

Loading booms

Different booms adapted to vessel size: slewing, telescopic, with luffing, with kicking...

Connection with facilities

Bucket elevator, tripper, transfer conveyor, slewing conveyor, fix connection point...

Other

Many accessories and options: filter, operator cabin, remote support, climate adaptation, ATEX, chemical adaptation, retrofitting of VIGAN technology on other loader brands...

Designed for almost any kind of products in bulk... VIGAN loaders are suitable for all size of barges or vessels

Downloads

Ship loaders - Leaflet

PDF

1.72 Mo

Ship loaders - Leaflet

PDF

1.72 Mo